Our Services

Our Services Overview

Integrate your project team with our services to provide the design expertise that you need and ensure the overall success of your product launch.

Orca Creation’s experienced engineers and program managers work as a team in delivering a total solution at any stage of product development and NPI cycle. We assist in product design, product industrialization and initial feasibility study to identify client needs, concept creation, technology study, product development and testing, detail design efforts, as well as undertaking an integration service of procurement and manufacturing management.

We are comprehensive team focusing on client wants and needs as well as providing versatile engineering solutions. In addition, at Orca Creation we provide solutions that take into account your manufacturing needs. Your engagement to Orca Creation services provides a signification impact on Time to Market and a resultant improvement in profitability.

Product Development

Our years of experience in mechanism and enclosure design as well as other engineering services provide us with valuable exposures to product development industry.

Industrial design

Mechanical Design

Electronic Design

Prototyping

Tooling & Manufacturing

You will have a dedicated Program Manager work with you throughout the entire process from design to manufacturing. With a single contact window to you, it simplifies the communication process and assures effectiveness in execution within the team to achieve your ultimate goal

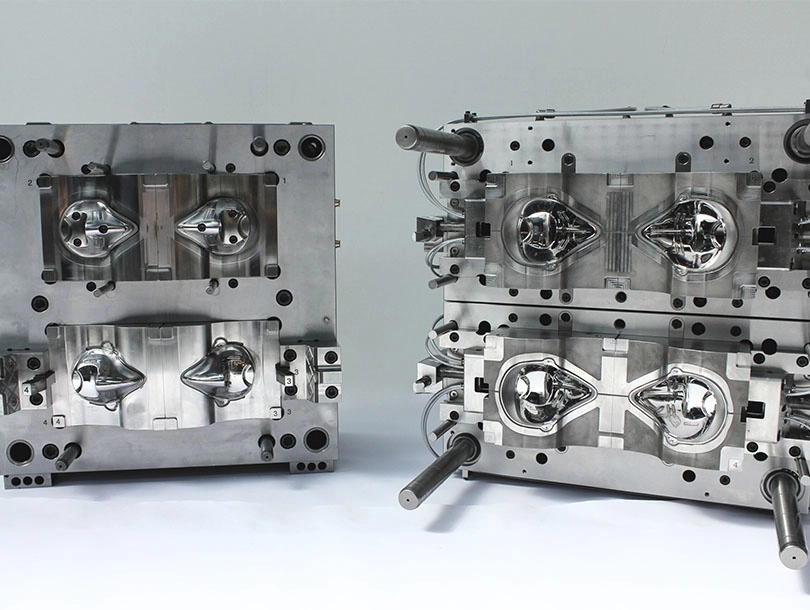

Tooling & Parts Fabrication

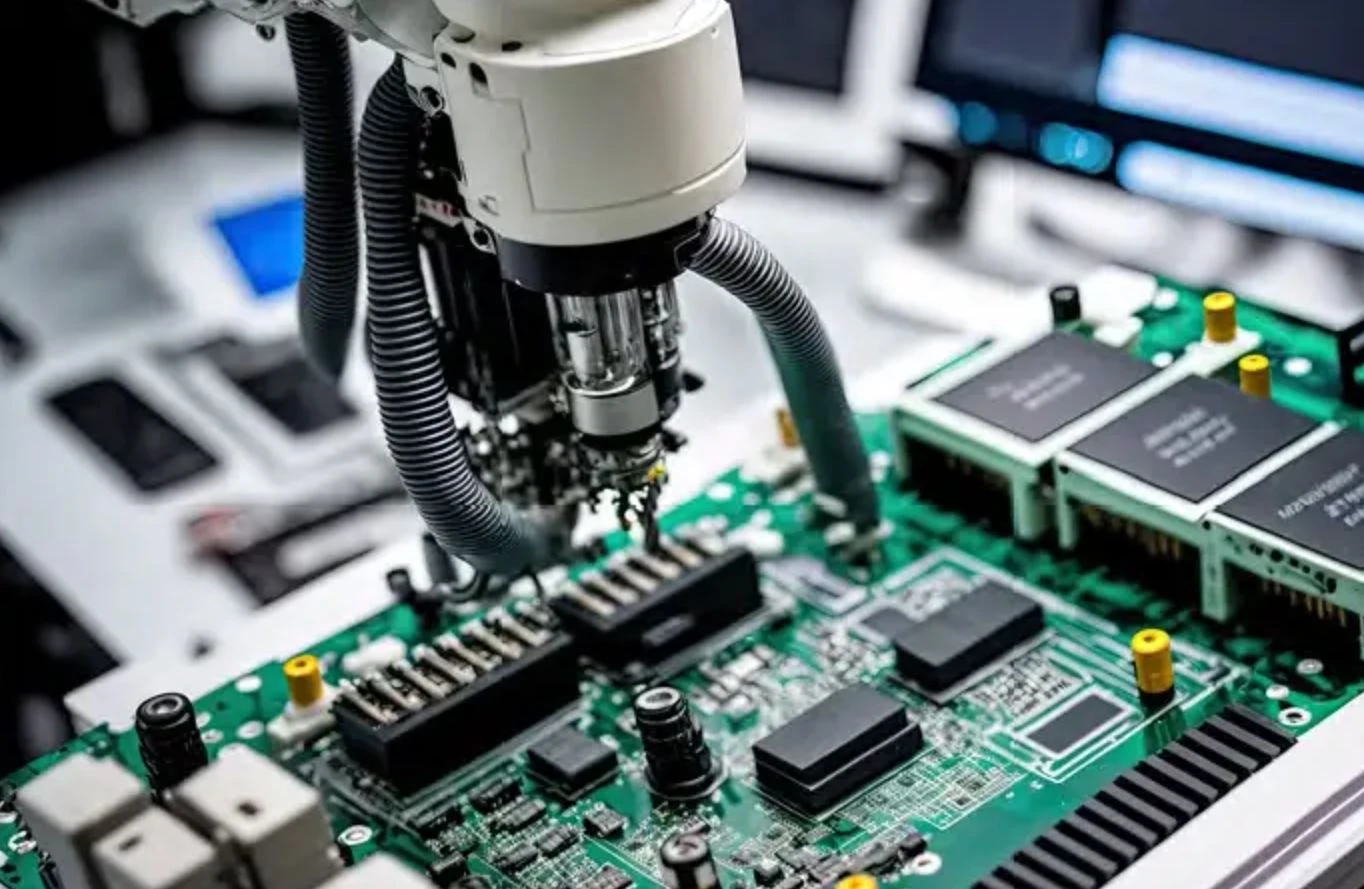

PCB Assemblies (PCBA)

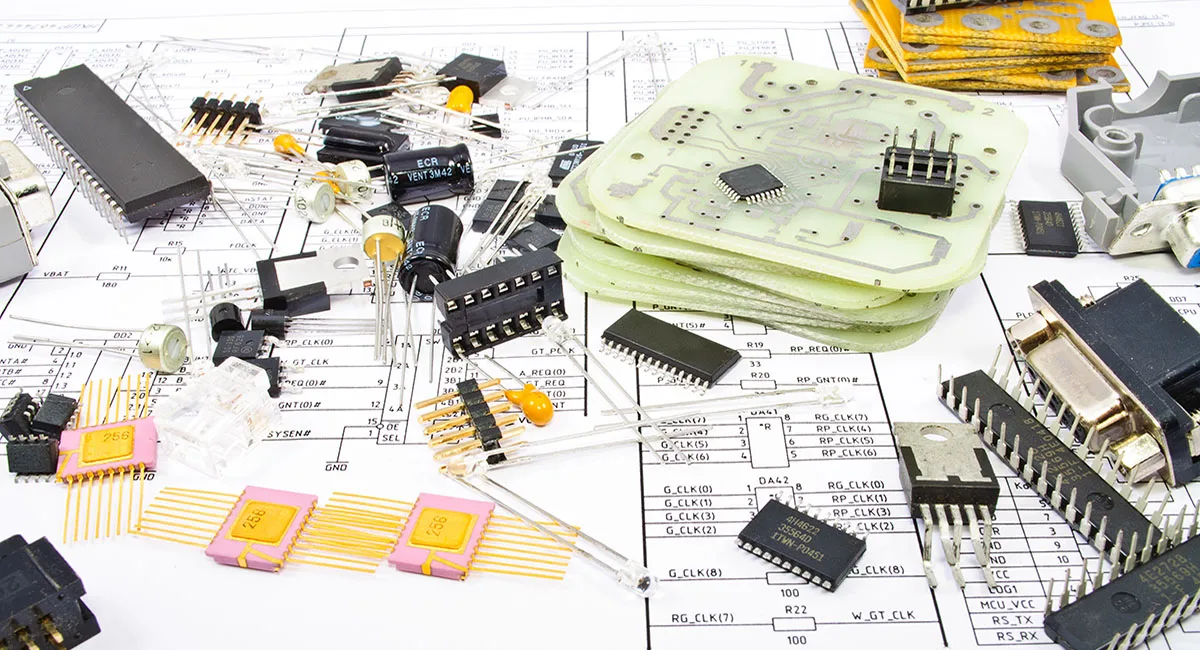

Component Sourcing

Product Manufacturing

Product Development Solutions (PDS)

Our years of experience in mechanism and enclosure design as well as engineering services provide us with valuable exposures to product development industry.

01

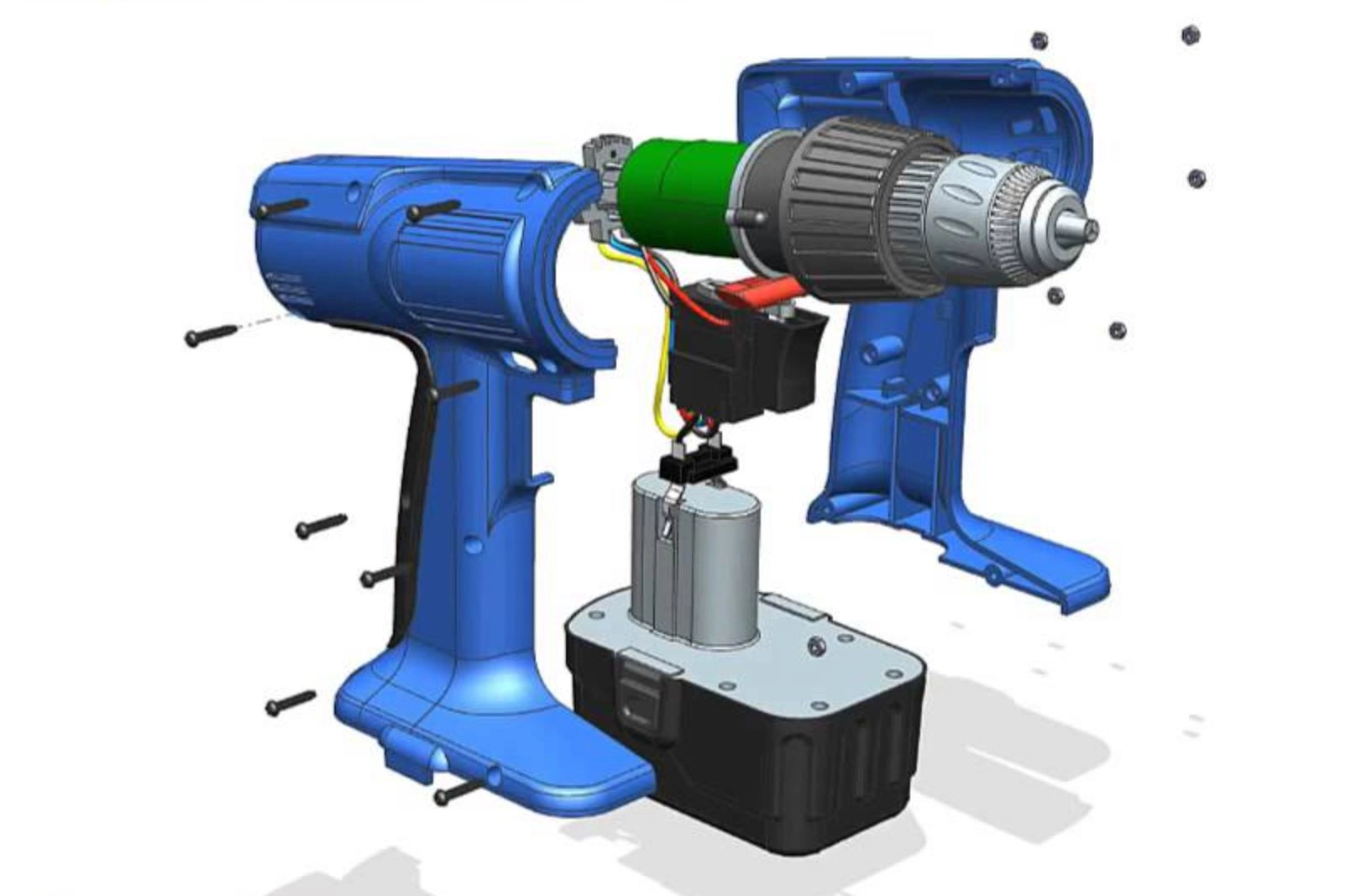

Mechanical Design Services

- Industrial design

- Product architecture design

- Product enclosure design

- Mechanism design

- Electronic development

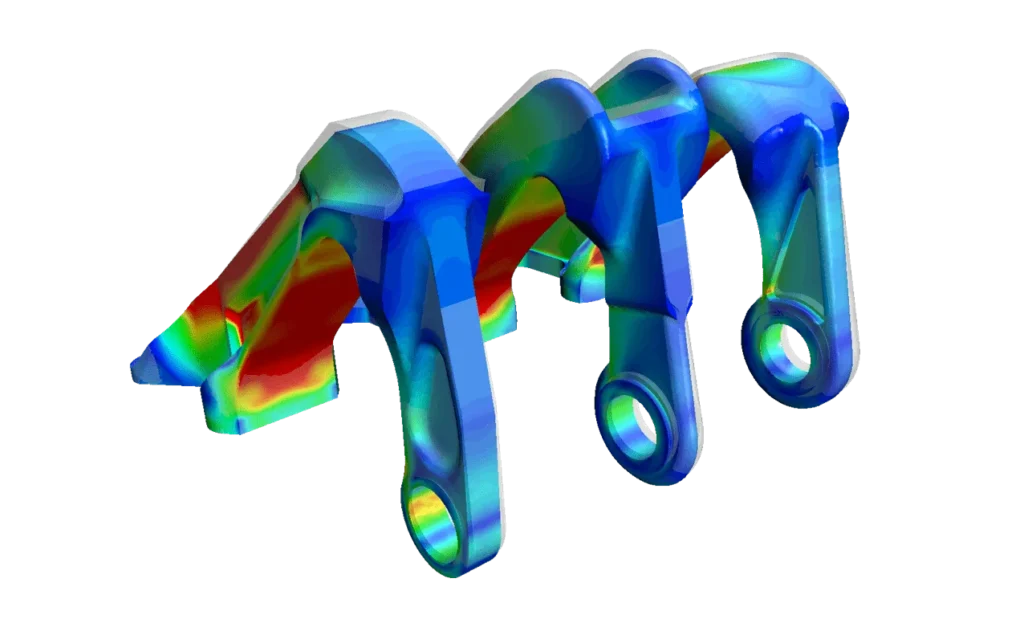

- Engineering analysis

02

Product Development Consultancy

- Design review and design quality assurance

- Engineering Analysis

- CAE Analysis

- Mold flow and manufacturability consultancy

- Manufacturing release & Engineering support

Product Industrialization Solutions (PIS)

Understanding and meeting the customer’s master plan is crucial in project management. From initial design concept right up to manufacturing, our PM team undertakes to develop appropriate project management strategies, attuned to customer guidelines.

01

New Product Introduction (NPI)

- Prototyping Management

- Tooling Management

- Engineering Evaluation Management

02

Material Supply Chain

- Component Level (Components, Parts)

- Assembly Level (Sub Assembly, Box Build)

Industrial design

- Award winning designs (Red Dot, IDEA, DEmark, iF pda …)

- Brainstorming & product ideation

- Preliminary sketches

- Renderings, logics and storyboards

- ID, mechanical, electrical, software and UI concepts

- Class A surfaces for ME templates

- Visual aids, models mockups, material samples & conceptual prototypes

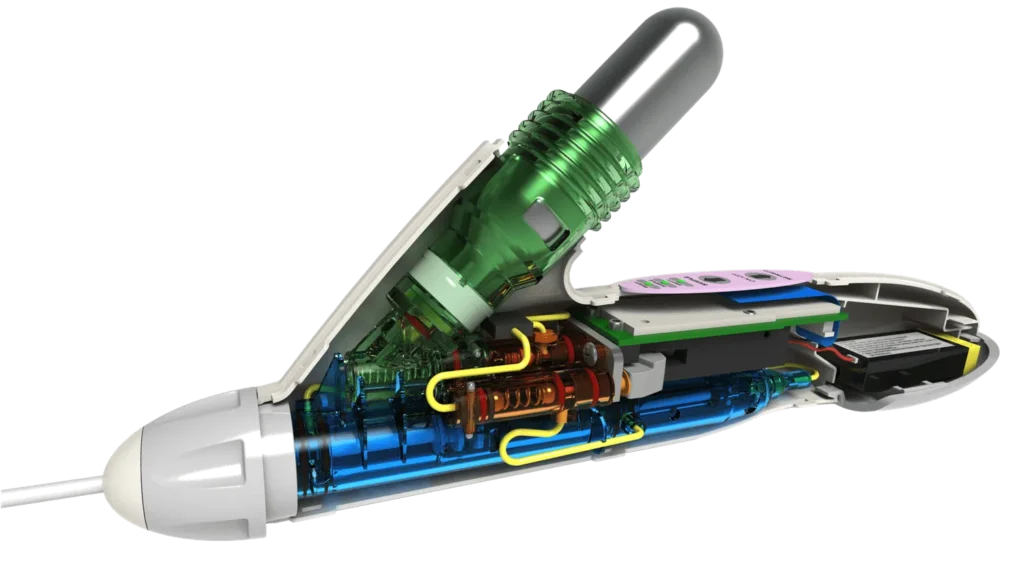

Mechanical Design

- Innovative designs that bridge concept to manufacturing

- Cost efficient, manufactureable designs

- Intellectual property transferrable to the customer

- Complete 3D solid models of all components

- Full product documentation and legacy support.

- Range of analysis including FEA and MFA.

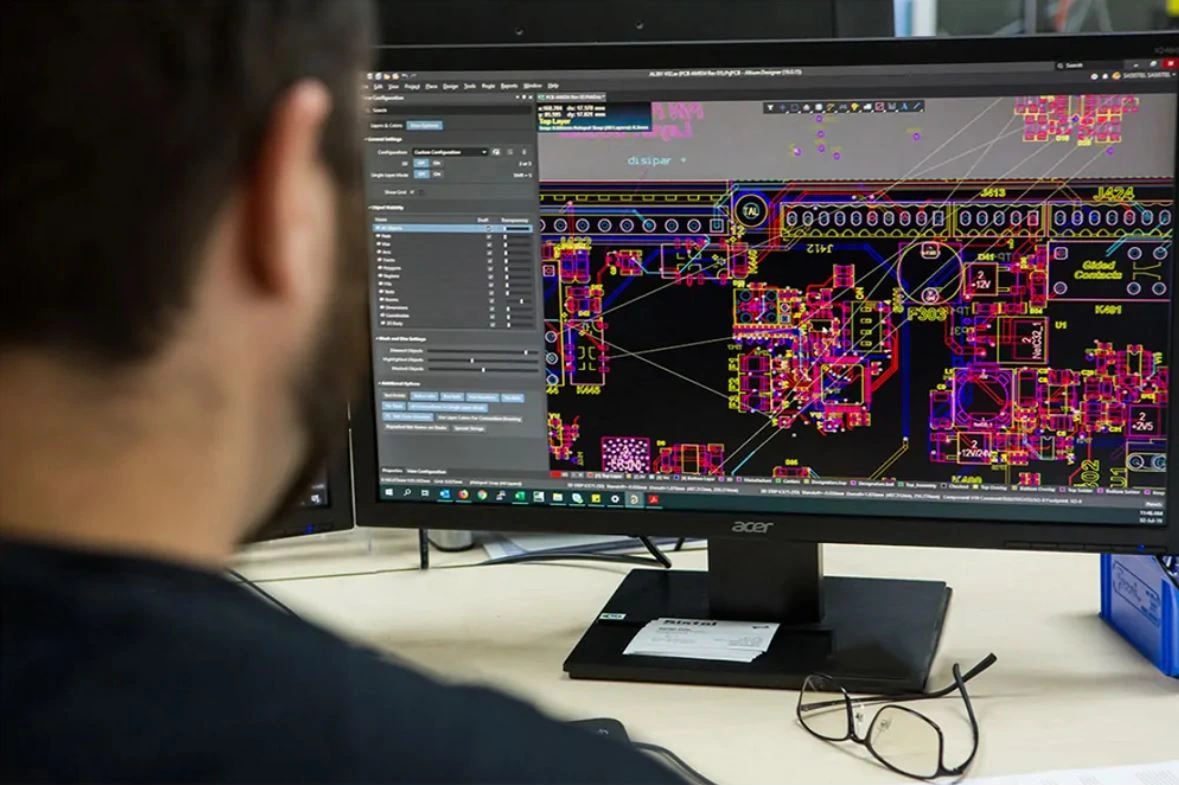

Electronic Design

- Embedded hardware and firmware design

- Develop custom circuitry or adapt your existing designs

- Full Gerber files and BOMs ready for manufacturing

- Extensive IoT experience

- Support for a broad range of software libraries

- Custom device drivers

Prototyping

- Turn ideas into detailed CAD models.

- Quick 3D printing, CNC, or laser cutting.

- Validate form, fit, and function.

- Choose the best materials for your project.

- Combine electronics and mechanics.

- Refine and optimize with feedback.

Tooling & Parts Fabrication

- ISO 9001, 13485, 14001 and 16949 certified facilities

- ISO Class 7 & 8 clean room molding

- SQF (Safe Quality Food) certified facilities

- Modern, closed-loop, computer controlled equipment

- Presses ranging from 10 to 2,550 tons

- Low-volume (<10K) to ultra-high (>10MM) annual volume molding

PCB Assemblies (PCBA)

- ISO 9001, 13485 and 14001 certified facilities

- Fully automated SMT (Surface Mount technology)

- Through-hole with wave solder cells and lines

- Flexible modular cell production systems for fast turn around and prototype

- Inline Integrated QMS and component testing

- Inline programming and testing capabilities

Component Sourcing

- Dedicated project manager (PM) for each customer

- Transparent top-level scheduling visibility with regular update intervals

- Purchasing and component management reports directly to team PM

- All departmental leads report real-time to PM for top-level roll up

- PM maintains continuity and ownership throughout project

- Custom reports and update intervals per request

Product Manufacturing

- ISO 9001, 13485, 14001 and 16949 certified facilities

- Clean room and SQF (Safe Quality Food) facility options

- Automated lines for high volume manufacturing

- Cell-based lines for low-to-medium manufacturing volumes

- Custom programming, serialization and testing procedures

- Integrated QMS and tracking

Connect With Us

Get in touch with us to discuss how our experts can bring your ideas to life.